Features£º

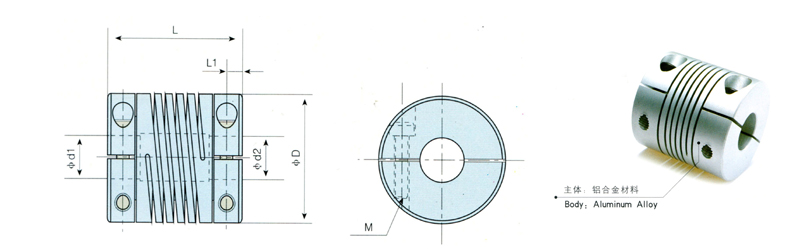

One-piece metallic spring coupling

Zero backlash

Absorption of parallel, angular misalignments and shaft end-play by spring action

Clamp type

Aluminum alloy and stainless steel

Dimensions |

||||||

Model |

Bore |

¡ÓD |

L |

L1 |

M |

Wrench Torque |

¡Ód1¡Ód2 |

(mm) |

(mm) |

(mm) |

¡¡ | £¨N.m) |

|

LJ-075 |

3-6.35 |

19.1 |

22.9 |

3.1 |

M2.5 |

1 |

LJ-100 |

5-10.0 |

25.4 |

31.8 |

4.15 |

M3 |

1.5 |

LJ-112 |

6-12.7 |

28.6 |

38.1 |

5 |

M3 |

2 |

LJ-150 |

8-15.0 |

38.1 |

41.3 |

5.9 |

M5 |

4 |

LJ-200 |

12-19.0 |

50.8 |

51 |

6.7 |

M6 |

7.5 |

Specifitions |

|||||||||

Model |

Rated Torque |

Max.Torque |

Max.Rotaional Frequency |

Moment of lnertia |

Static Torsional Stiffness |

Errors of Eccentricity |

Errors of Angularity |

Errors of Shaft End-play |

Mass |

£¨N.m) |

£¨N.m) |

£¨rpm) |

kg.©O |

(N.m/rad) |

(mm) |

(¡æ£© |

£¨mm) |

(g) |

|

LJ-075 |

0.5 |

1 |

8000 |

9.0X10-7 |

110 |

0.1 |

2 |

¡À0.15 |

14 |

LJ-100 |

1.4 |

2.8 |

6000 |

2.6X10-6 |

170 |

0.1 |

2 |

¡À0.15 |

34 |

LJ-112 |

1.6 |

3.2 |

5000 |

8.9X10-6 |

260 |

0.1 |

2 |

¡À0.15 |

48 |

LJ-150 |

4.2 |

8.4 |

4500 |

3.2X10-5 |

330 |

0.1 |

2 |

¡À0.15 |

96 |

LJ-200 |

9.0 |

18 |

4500 |

9.8X10-5 |

560 |

0.1 |

2 |

¡À0.15 |

140 |

Features£º

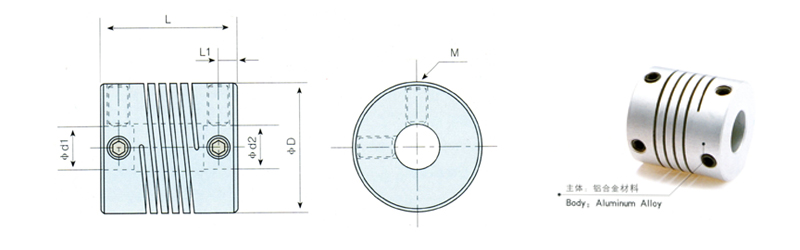

One-piece metallic spring coupling

Zero backlash

Absorption of parallel, angular misalignments and shaft end-play by spring action

Absorption of large angular misalignments by spring action

Setscrew type

Material: Aluminum alloy and stainless steel

Dimensions |

||||||

Model |

Bore |

¡ÓD |

L |

L1 |

M |

Wrench Torque |

¡Ód1¡Ód2 |

(mm) |

(mm) |

(mm) |

¡¡ | £¨N.m) |

|

LD-075 |

3-6.35 |

19.1 |

22.9 |

3.1 |

M2.5 |

1 |

LD-100 |

5-10.0 |

25.4 |

31.8 |

4.15 |

M3 |

1.5 |

LD-112 |

6-12.7 |

28.6 |

38.1 |

5 |

M3 |

2 |

LD-150 |

8-15.0 |

38.1 |

41.3 |

5.9 |

M5 |

4 |

LD-200 |

12-19.0 |

50.8 |

51 |

6.7 |

M6 |

7.5 |

Specifications |

|||||||||

Model |

Rated Torque |

Max. Torque |

Max. Rotational Frequency |

Moment of inertia |

Static torsional stiffness |

Errors of Eccentricity |

Errors of Angularity |

Errors of shaft end-play |

Mass |

£¨N.m) |

£¨N.m) |

£¨rpm) |

kg.©O |

(N.m/rad) |

(mm) |

(¡æ£© |

£¨mm) |

(g) |

|

LJ-075 |

0.5 |

1 |

8000 |

9.0X10-7 |

110 |

0.1 |

2 |

¡À0.15 |

14 |

LJ-100 |

1.4 |

2.8 |

6000 |

2.6X10-6 |

170 |

0.1 |

2 |

¡À0.15 |

34 |

LJ-112 |

1.6 |

3.2 |

5000 |

8.9X10-6 |

260 |

0.1 |

2 |

¡À0.15 |

48 |

LJ-150 |

4.2 |

8.4 |

4500 |

3.2X10-5 |

330 |

0.1 |

2 |

¡À0.15 |

96 |

LJ-200 |

9.0 |

18 |

4500 |

9.8X10-5 |

560 |

0.1 |

2 |

¡À0.15 |

140 |

Features£º

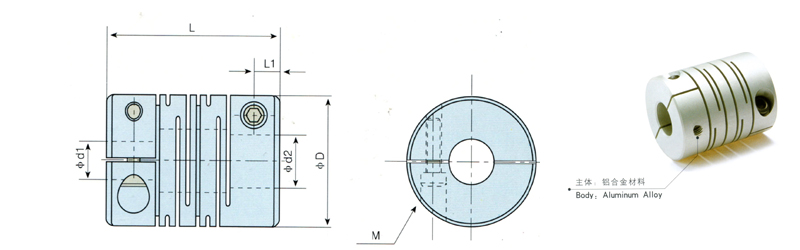

One-piece metallic spring coupling

Zero Backlash

Absorption of parallel, angular misalignments and shaft end-play by spring action

Idential clockwise and anticlockwise rotational characteristics

Clamp type

Material: Aluminum Alloy and stainless stell

Dimensions |

||||||

Model |

Bore |

¡ÓD |

L |

L1 |

M |

Wrench torque |

¡Ód1¡Ód2 |

(mm) |

(mm) |

(mm) |

¡¡ | £¨N.m) |

|

PJ-075 |

3-6.35 |

19.1 |

22.9 |

3.1 |

M2.5 |

1 |

PJ-100 |

5 6 6.35 8 10 |

25.4 |

31.8 |

4.15 |

M3 |

1.5 |

PJ-112 |

6 6.35 8 10 12.7 |

28.6 |

38.1 |

5 |

M3 |

2 |

PJ-150 |

8 10 12 12.7 14 15 |

38.1 |

41.3 |

5.9 |

M5 |

4 |

PJ-200 |

12 12.7 14 15 16 18 19 |

50.8 |

51 |

6.7 |

M6 |

7.5 |

Specifications |

|||||||||

Model |

Rated Torque |

Max. Torque |

Max. Rotational Frequency |

Moment of Inertia |

Static Torsional Stiffness |

Errors of Eccentricity |

Errors of Angularity |

Errors of shaft End-play |

Mass |

£¨N.m) |

£¨N.m) |

£¨rpm) |

kg.©O |

(N.m/rad) |

(mm) |

(¡æ£© |

£¨mm) |

(g) |

|

PJ-075 |

0.5 |

1 |

8000 |

9.0X10-7 |

110 |

0.1 |

1.5 |

¡À0.15 |

14 |

PJ-100 |

1.4 |

2.8 |

6000 |

2.5X10-6 |

170 |

0.1 |

1.5 |

¡À0.15 |

32 |

PJ-112 |

1.6 |

3.2 |

5000 |

8.8X10-6 |

260 |

0.1 |

1.5 |

¡À0.15 |

46 |

PJ-150 |

4.2 |

8.4 |

4500 |

3.0X10-5 |

330 |

0.1 |

1.5 |

¡À0.15 |

92 |

PJ-200 |

9.0 |

18 |

4500 |

9.6X10-5 |

560 |

0.1 |

1.5 |

¡À0.15 |

136 |

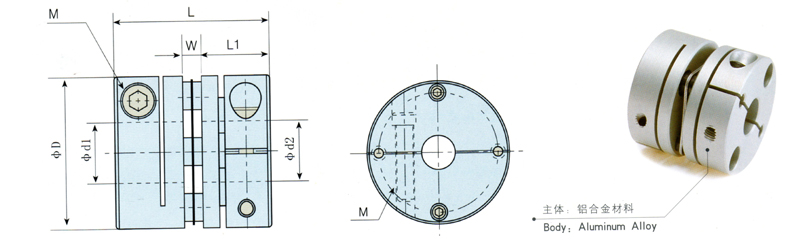

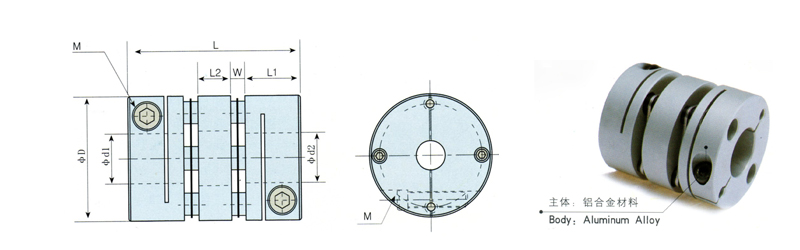

Features£º

Excellent response and high torque capacity

Zero Backlash

Stainless steel plate springs absorb angular misalignment and shaft end-play

Idential Clockwise and anticlockwise rotational characteristics

Clamp type

Usually connect Servo motor and stepper motor

Dimensions |

||||||||

Model |

Bore |

¡ÓD |

L |

W |

L1 |

M |

Wrench |

¡¡ |

¡Ód1¡Ód2 |

(mm) |

(mm) |

(mm) |

(mm) |

¡¡ | £¨N.m) |

¡¡ | |

DM-019 |

3-8.0 |

19 |

20 |

1.2 |

9.4 |

M2.5 |

1 |

¡¡ |

DM-026 |

5-10.0 |

26 |

25.5 |

2.5 |

11.5 |

M3 |

1.5 |

¡¡ |

DM-034 |

8-14.0 |

34 |

31.3 |

3.1 |

14.1 |

M4 |

1.5 |

¡¡ |

DM-039 |

10-16.0 |

39 |

34.1 |

4.1 |

15 |

M4 |

2.5 |

¡¡ |

DM-044 |

11-19.0 |

44 |

34.5 |

4.5 |

15 |

M4 |

2.5 |

¡¡ |

DM-056 |

14-24 |

56 |

45 |

5 |

20 |

M5 |

7 |

¡¡ |

DM-068 |

19-35 |

68 |

54 |

6 |

24 |

M6 |

12 |

¡¡ |

DM-082 |

24-40 |

82 |

68 |

8 |

30 |

M8 |

16 |

¡¡ |

DM-094 |

25-40 |

94 |

68 |

8 |

30 |

M8 |

28 |

¡¡ |

DM-104 |

30-45 |

104 |

70 |

10 |

30 |

M8 |

28 |

¡¡ |

Specifications |

||||||||

Model |

Rated Torque |

Max. Torque |

Max. Rotational Frequency |

Moment of Inertia |

Static Torsional Stiffness |

Errors of Angularity |

Errors of shaft end-play |

Mass |

£¨N.m) |

£¨N.m) |

£¨rpm) |

kg.©O |

(N.m/rad) |

(¡æ£© |

£¨mm) |

(g) |

|

DM-019 |

1 |

2 |

10000 |

0.65X10-6 |

200 |

1 |

¡À0.2 |

12 |

DM-026 |

1.4 |

2.8 |

10000 |

1.8X10-6 |

690 |

1 |

¡À0.2 |

24 |

DM-034 |

2.8 |

5.6 |

10000 |

7.2X10-6 |

1650 |

1 |

¡À0.2 |

46 |

DM-039 |

5.8 |

11.6 |

10000 |

1.8X10-5 |

2500 |

1 |

¡À0.2 |

78 |

DM-044 |

8.7 |

17.4 |

10000 |

2.5X10-5 |

2900 |

1 |

¡À0.2 |

96 |

DM-056 |

25.0 |

50 |

10000 |

1.0X10-4 |

8400 |

1 |

¡À0.2 |

206 |

DM-068 |

55.0 |

110 |

10000 |

1.9X10-4 |

11500 |

1 |

¡À0.2 |

366 |

DM-082 |

80.0 |

160 |

10000 |

7.0X10-4 |

14550 |

1 |

¡À0.2 |

710 |

DM-094 |

185.0 |

370 |

10000 |

1.23X10-3 |

16900 |

1 |

¡À0.2 |

960 |

DM-104 |

255.0 |

510 |

10000 |

1.86X10-3 |

25100 |

1 |

¡À0.2 |

1190 |

Dimensions |

||||||||

Model |

Öᾶ |

¡ÓD |

L |

W |

L1 |

L2 |

M |

Wrench Torque |

¡Ód1¡Ód2 |

(mm) |

(mm) |

(mm) |

(mm) |

(mm) |

¡¡ | £¨N.m) |

|

SM-019 |

3-8 |

19 |

27 |

1.2 |

9.4 |

5.8 |

M2.5 |

1 |

SM-026 |

5-10 |

26 |

35 |

2.5 |

11.5 |

7 |

M3 |

1.5 |

SM-034 |

8-14 |

34 |

45 |

3.1 |

14.1 |

10.6 |

M4 |

1.5 |

SM-039 |

10-16 |

39 |

49 |

4.1 |

15 |

10.8 |

M4 |

2.5 |

SM-044 |

11-19 |

44 |

50 |

4.5 |

15 |

11 |

M4 |

2.5 |

SM-056 |

14-24 |

56 |

63 |

5 |

20 |

13 |

M5 |

7 |

SM-068 |

19-35 |

68 |

74 |

6 |

24 |

14 |

M6 |

12 |

SM-082 |

24-40 |

82 |

98 |

8 |

30 |

22 |

M8 |

16 |

SM-094 |

25-40 |

94 |

98 |

8 |

30 |

22 |

M8 |

28 |

SM-104 |

30-45 |

104 |

102 |

10 |

30 |

22 |

M8 |

28 |

Specifications |

||||||||

Model |

Rated Torque |

Max. Torque |

Max. Rotational Frequency |

Moment of Inertia |

Static Torsional Stiffness |

Errors of Angularity |

Errors of Shaft end-play |

Mass |

£¨N.m) |

£¨N.m) |

£¨rpm) |

kg.©O |

(N.m/rad) |

(¡æ£© |

£¨mm) |

(g) |

|

SM-019 |

1 |

2 |

10000 |

0.9X10-6 |

170 |

1.5 |

¡À0.4 |

16 |

SM-026 |

1.4 |

2.8 |

10000 |

3.3X10-6 |

950 |

1.5 |

¡À0.4 |

34 |

SM-034 |

2.8 |

5.6 |

10000 |

8.9X10-6 |

1960 |

1.5 |

¡À0.4 |

70 |

SM-039 |

5.8 |

11.6 |

10000 |

2.4X10-5 |

4500 |

1.5 |

¡À0.4 |

118 |

SM-044 |

8.7 |

17.4 |

10000 |

3.2X10-5 |

5100 |

1.5 |

¡À0.4 |

142 |

SM-056 |

25.0 |

50 |

10000 |

1.1X10-4 |

10500 |

1.5 |

¡À0.4 |

296 |

SM-068 |

55.0 |

110 |

10000 |

2.8X10-4 |

18500 |

1.5 |

¡À0.4 |

544 |

SM-082 |

80.0 |

160 |

10000 |

1.0X10-3 |

21800 |

1.5 |

¡À0.4 |

1020 |

SM-094 |

185.0 |

370 |

10000 |

1.76X10-3 |

84500 |

1.5 |

¡À0.4 |

1210 |

SM-104 |

255.0 |

510 |

10000 |

1.86X10-3 |

125500 |

1.5 |

¡À0.4 |

1460 |

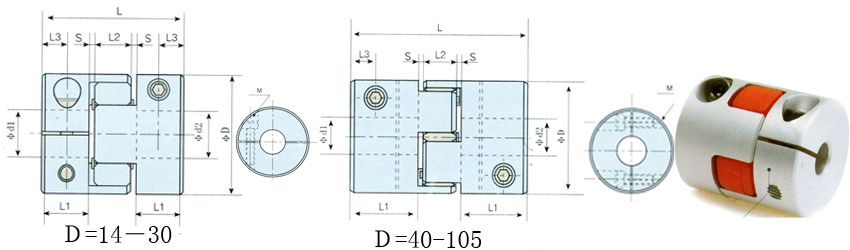

Features£º

Absorb vibration, parallel, angular misalignments and shaft end-play

Identical clockwise and anticlockwise rotational characteristics

Resistant to oil corrosion and electrical insulation

Clamp type

Usually connect servo motor and stepper motor

Dimensions |

|||||||||

Model |

Bore |

¡ÓD |

L |

L1 |

L2 |

S |

L3 |

M |

Wrench Torque |

¡Ód1¡Ód2 |

(mm) |

(mm) |

(mm) |

(mm) |

(mm) |

(mm) |

¡¡ | £¨N.m) |

|

MJ-14 |

2-7.0 |

14 |

22 |

7 |

6 |

1 |

3.5 |

M3 |

1 |

MJ-20 |

4-10.0 |

20 |

30 |

10 |

8 |

1 |

5 |

M4 |

1.3 |

MJ-25 |

4-12.0 |

25 |

34 |

11 |

10 |

1 |

5 |

M4 |

1.5 |

MJ-30 |

8-16.0 |

30 |

35 |

11 |

10 |

1.5 |

5 |

M4 |

1.7 |

MJ-40 |

14-24 |

40 |

66 |

25 |

12 |

2 |

10 |

M5 |

4 |

MJ-55 |

14-28 |

55 |

78 |

30 |

14 |

2 |

10 |

M5 |

4 |

MJ-65 |

19-38 |

65 |

90 |

35 |

15 |

2.5 |

15 |

M8 |

15 |

MJ-80 |

24-45 |

80 |

114 |

45 |

18 |

3 |

15 |

M8 |

15 |

MJ-95 |

30-55 |

95 |

126 |

50 |

20 |

3 |

20 |

M8 |

15 |

MJ-100 |

35-60 |

105 |

140 |

56 |

21 |

3.5 |

20 |

M8 |

15 |

Specifications |

|||||||||

Model |

Rated Torque |

Max. Torque |

Max. Rotational Frequency |

Moment Inertia |

Static Torsional Stiffness |

Errors of Eccentricity |

Error of Angularity |

Errors of Shaft end-play |

Mass |

£¨N.m) |

£¨N.m) |

£¨rpm) |

kg.©O |

(N.m/rad) |

(mm) |

(¡æ£© |

£¨mm) |

(g) |

|

MJ-14 |

1.1 |

2.2 |

19000 |

5.9X10-4 |

46 |

0.02 |

1 |

0.6 |

26 |

MJ-20 |

2.8 |

5.6 |

17000 |

6.7X10-4 |

55 |

0.02 |

1 |

0.6 |

37 |

MJ-25 |

6 |

12 |

16000 |

7.6X10-4 |

63 |

0.02 |

1 |

0.6 |

42 |

MJ-30 |

6.5 |

13 |

15000 |

8.5X10-4 |

72 |

0.02 |

1 |

0.6 |

46 |

MJ-40 |

32.0 |

64 |

13000 |

1.1X10-3 |

550 |

0.02 |

1 |

0.8 |

148 |

MJ-55 |

46 |

92 |

10500 |

4.4X10-3 |

1500 |

0.02 |

1 |

0.8 |

350 |

MJ-65 |

109 |

218 |

8300 |

9.0X10-3 |

2800 |

0.02 |

1 |

0.8 |

572 |

MJ-80 |

135 |

270 |

7000 |

1.8X10-2 |

3500 |

0.02 |

1 |

1 |

950 |

MJ-95 |

260 |

520 |

6000 |

2X10-2 |

4600 |

0.02 |

1 |

1 |

1800 |

MJ-100 |

430 |

860 |

5500 |

3.2X10-2 |

5800 |

0.02 |

1 |

1 |

2400 |

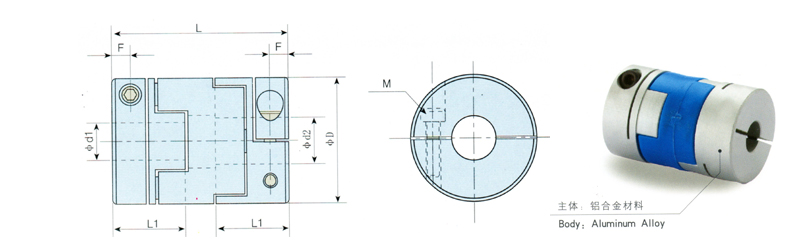

Features£º

High torque capacity and excellent response

Allow high parallel and angular misalignments

Zero Backlash

Resistant to oil corrosion and electrical insulation

Clamp type

Dimensions |

|||||||

Model |

Bore |

¡ÓD |

L |

F |

L1 |

M |

Wrench Torque |

¡Ód1¡Ód2 |

¡¡ | ¡¡ | ¡¡ | ¡¡ | ¡¡ | £¨N.m) |

|

SJ-16 |

4-6.0 |

16 |

30 |

3 |

13 |

M2.5 |

0.7 |

SJ-20 |

6-8.0 |

20 |

33 |

3 |

14 |

M2.5 |

1.7 |

SJ-25 |

6-10.0 |

25 |

39 |

3.8 |

17 |

M3 |

4 |

SJ-32 |

8-14.0 |

32 |

45 |

4.5 |

19 |

M4 |

7 |

SJ-40 |

12-16.0 |

40 |

50 |

7 |

23 |

M5 |

7 |

SJ-50 |

14-20 |

50 |

58 |

8 |

27 |

M6 |

15 |

SJ-63 |

16-25 |

63 |

71 |

10 |

33 |

M8 |

30 |

Specifications |

||||||||

Model |

Rated Torque |

Max Torque |

Max. Rotational Frequency |

Moment Inertia |

Static torsional Stiffness |

Errors of Eccentricity |

Errors Angularity |

Mass |

£¨N.m) |

£¨N.m) |

£¨rpm) |

kg.©O |

(N.m/rad) |

(mm) |

(¡æ£© |

(g) |

|

SJ-16 |

0.7 |

1.4 |

9000 |

5X10-7 |

29 |

1 |

3 |

12 |

SJ-20 |

1.6 |

3.2 |

7400 |

1.4X10-7 |

58 |

1.4 |

3 |

20 |

SJ-25 |

3 |

6 |

5800 |

4.1X10-6 |

125 |

1.9 |

3 |

36 |

SJ-32 |

5.5 |

11 |

4700 |

1.2X10-5 |

260 |

2.4 |

3 |

66 |

SJ-40 |

9.0 |

18 |

3600 |

3.8X10-5 |

505 |

2.8 |

3 |

114 |

SJ-50 |

19 |

38 |

3000 |

1X10-4 |

780 |

3.3 |

3 |

206 |

SJ-63 |

33 |

66 |

2400 |

3.5X10-4 |

1200 |

3.8 |

3 |

454 |

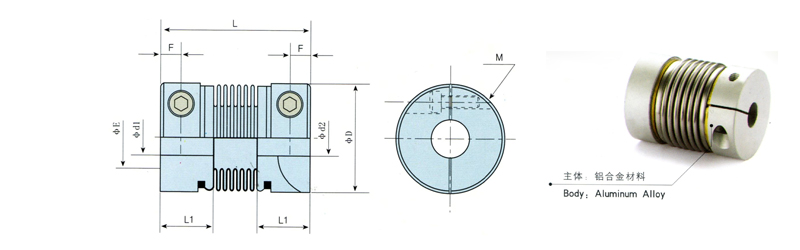

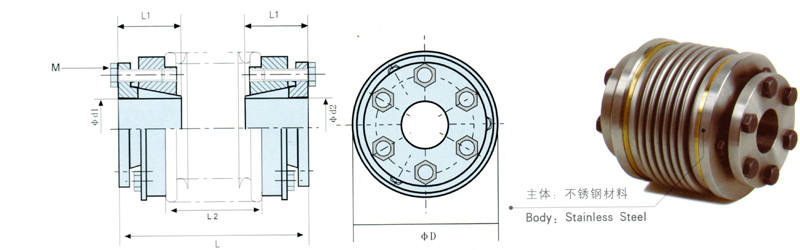

Features£º

High rotational Torque capacty and excellent response

Zero backlash

Spring action bellows configuration absorbs parallel, angular misalgnments and shaft end-play

Idential clockwise and anticlockwise rotational characteristics

Clamp type

Dimensions |

||||||||

Model |

Bore |

¡ÓD |

L |

L1 |

F |

E |

M |

Wrench Torque |

¡Ód1¡Ód2 |

¡¡ | ¡¡ | ¡¡ | ¡¡ | ¡¡ | ¡¡ | £¨N.m) |

|

BJ-16 |

4-8.0 |

16 |

30 |

10.5 |

4 |

9.5 |

M3 |

0.7 |

BJ-20 |

6.0-12 |

20 |

33 |

10.5 |

4 |

12.5 |

M3 |

0.7 |

BJ-25 |

6.0-12 |

25 |

38 |

12.5 |

5 |

15 |

M4 |

1.7 |

BJ-32 |

8.0-14 |

32 |

43 |

14 |

6 |

21 |

M4 |

1.7 |

BJ-32L |

8.0-14 |

32 |

54 |

14 |

6 |

21 |

M4 |

1.7 |

BJ-40 |

10.0-16 |

40 |

62 |

21.5 |

6.5 |

27 |

M5 |

4 |

BJ-55 |

12-19.0 |

55 |

72 |

23 |

7 |

40 |

M6 |

8 |

BJ-65 |

18-38 |

65 |

81 |

25.5 |

9 |

45 |

M8 |

15 |

BJ-82 |

20-42 |

82 |

103 |

34.5 |

11 |

5.6 |

M10 |

28 |

Specifications |

|||||||||

Model |

Rated Torque |

Max. Torque |

Max. Rotationsl Frequency |

Moment of Inertia |

Static Torsional Stiffness |

Erros of Eccentricity |

Errors of Angularity |

Errors of shaft end-play |

Mass |

£¨N.m) |

£¨N.m) |

£¨rpm) |

kg.©O |

(N.m/rad) |

(mm) |

(¡æ£© |

(mm) |

(g) |

|

BJ-16 |

0.8 |

1.6 |

18000 |

3.4X10-7 |

100 |

0.1 |

1.5 |

¡¡ +0.3,-1 | 8 |

BJ-20 |

1.5 |

3 |

13000 |

8.9X10-7 |

160 |

0.1 |

1.5 |

¡¡ +0.3,-1 | 14 |

BJ-25 |

2 |

4 |

11000 |

2.8X10-6 |

220 |

0.15 |

2 |

¡¡ +0.5,-1.3 | 32 |

BJ-32 |

2.5 |

5 |

10000 |

8.8X10-6 |

310 |

0.2 |

2 |

¡¡ +0.5,-1.3 | 52 |

BJ-32L |

2.5 |

5 |

10000 |

8.9X10-6 |

310 |

0.2 |

2 |

¡¡ +0.5,-1.3 | 58 |

BJ-40 |

10.0 |

20 |

8000 |

1.5X10-5 |

520 |

0.2 |

2 |

¡¡ +0.7,-1.5 | 98 |

BJ-55 |

25 |

50 |

6000 |

2.3X10-5 |

850 |

0.2 |

2 |

¡¡ +0.7,-1.5 | 200 |

BJ-65 |

60 |

120 |

4500 |

2.8X10-5 |

960 |

0.2 |

2 |

¡¡ +0.7,-1.5 | 350 |

BJ-82 |

80 |

160 |

4000 |

6X10-5 |

1290 |

0.2 |

2 |

¡¡ +0.7,-1.5 | 750 |

Features£º

using locking assemblies connect, plate springs coupling

Easier to assembly and disassembly

Zero Backlash

Spring action bellows configuration absorbs parallel, angular misalgnments and shaft end-play

Identical clockwise and anticlockwise rotational characteristics

Bellow material is stainless steel

Dimensions |

|||||||

Model |

Bore |

¡ÓD |

L |

L1 |

L2 |

M |

Wrench Torque |

¡Ód1¡Ód2 |

¡¡ | ¡¡ | ¡¡ | ¡¡ | ¡¡ | £¨N.m) |

|

BZ-40 |

10.0-16 |

40 |

55 |

19 |

24 |

M4 |

3 |

BZ-55 |

11.0-20 |

55 |

65 |

22 |

31 |

M4 |

6 |

BZ-65 |

14-28 |

65 |

76 |

27 |

37 |

M5 |

8 |

BZ-82 |

19-38 |

82 |

88 |

32 |

41 |

M5 |

10 |

Specifications |

|||||||||

Model |

Rated Torque |

Max. Torque |

Max. Ratational Frequency |

Moment Inertia |

Statc Torsional Stiffness |

Errors of Eccentricity |

Errors of Angularity |

Errors of Shaft end-play |

Mass |

£¨N.m) |

£¨N.m) |

£¨rpm) |

kg.©O |

(N.m/rad) |

(mm) |

(¡æ£© |

(mm) |

(g) |

|

BZ-40 |

13 |

26 |

8000 |

9X10-5 |

1.5X104 |

0.15 |

2 |

1.00 |

210 |

BZ-55 |

28 |

56 |

6000 |

2.9X10-4 |

3.5X104 |

0.2 |

2 |

1.5 |

400 |

BZ-65 |

56 |

112 |

5000 |

4.6X10-4 |

6.8X104 |

0.25 |

2 |

1.5 |

790 |

BZ-82 |

120 |

240 |

4500 |

1.1X10-3 |

1.2X105 |

0.28 |

2 |

1.5 |

1210 |